GRIMS barcoding

From ICISWiki

Contents |

Introduction

In the old information system (IRGCIS), an accurate inventory was not maintained. For the base collection, the weight of seed was recorded as 60 g or 120 g depending on whether one or two Aluminium cans were stored, regardless of how much seed was actually in each can. For the bulk sample in the active collection, the weight of seed recorded was reduced by 10 g for each withdrawal of a sample of cultivated rice, and by the calculated 20-grain weight for each withdrawal of wild species. These computations accumulate inaccuracies in the recorded amount of seed stored, leading to unreliable decisions for other Genebank operations such as regeneration.

A barcoding system has been developed with a barcode reader attached to a digital balance. All seed packets in the active and base collections have been labelled with bar-coded labels. An application has been developed within the new Genetic Resources Information Management System (GRIMS) to transfer data on seed weights into the Inventory Management System (IMS) of the International Rice Information System (IRIS). Every time a new seed packet is added to the collection or an existing returned to storage, the weight of seed in the packet is recorded.

With the introduction of bar-coded labels, digital weighing, and automatic transfer of data on seed weights to, the inventory is now permanently accurate and constantly updated. The new system eliminates the labour and inaccuracy that results from manual weighing, approximate adjustments, and the recording, proofreading, and entry of data.

This page describes the procedures involved.

Workflow

Creating a seedlist for barcoding

- The system generates a batch identifier (i.e. LP-2006000001; Format: LP-YYYYXXXXXX; where LP=Labels printed,YYYY=year, and XXXXXX=sequence number) for the labels to be printed.

- The user can print barcodes by list of accession numbers or by location (tray number). If the input is tray number, the sytem gets all the accesions from that tray and produce the seed list. The user also has the option to input data from an ASCII file.

- The user needs to specify where to stick the barcode labels. There are two types of collection in the IRRI Genebank - the active collection and the base collection. The active collection are packaged into several types which are the following:

- Aluminum bulk (BULK) - Seeds that are stored in big aluminum bag.

- Aluminum packet (AP) - Initially 2 AP's are made for every successful seed increase or seed regeneration. If the AP's run out of stock, seeds are withdrawn from the bulk to create 2APs. (The actual amount of AP is not stored in the database but only the number of prepared APs is recorded.)

- Paper packet (PP) - This packet of seed is not distributed outside IRRI and is for internal Genebank use only (i.e. research).

- An option to exclude particular crop seasons when the seeds were produced is available. For example, the user can exclude accessions or harvests produced from 2006 Dry Season.

- The system is now ready for printing of barcode labels.

Printing of barcode labels

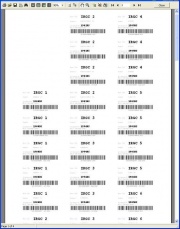

The barcode label contains the following information:

- IRGC accession number

- Germplasm name - The hierarchy of giving a name is as follows: 1) Variety name, 2) Donor accession number, and 3) Collector's number. Species name is given for wild species.

- Year and season when the seed packet was produced - Format: YYYYSS. The following are the valid crop season: 1) DS- dry season, 2) WS- wet season, and 3) SS - Unknown season (rare).

- Germplasm designation to MLS - Indicates if the germplasm is MLS designation or not.

- Barcode - Seed lot identifier (i.e. *GR-XXXXXXXXXX*; where "*" - a character terminator; GR - Genetic Resources; XXXXXXXXXX - Lot identifier

- Seed lot identifier and the tray number - The tray number is displayed in the label to facilitate ease of getting and transferring back the seed packet to its proper location.

The user has an option to continue on printing of labels right after creating the seedlist by pressing the [Print Labels] button OR create another seedlist for barcoding since he can print the labels from previously created seed list.

- To print labels from the previously created seedlist, press the [...] button beside the batch textbox. A look up values of previously created batches will appear. The user selects the batch of the seedlist that he wants to preview.

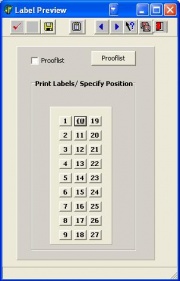

- Upon pressing of the [Print Labels] button, a form that shows the layout of the A4 sheet (where the labels will be printed) will appear.

- The user needs to press the button that corresponds to the next empty label position in an A4 sheet. For example, if the user wish to start the printing of labels in the 4th position, he needs to press the [4] button.

Sticking of labels

Several processes are involved to successfully stick the barcode labels onto the cans (base collection) or the foil packets (active collection).

The picture on the right shows the steps involved in labeling the base collection.

- The cans are taken from the store room by tray number.

- Accessions numbers in the tray are compared with the records in the database and labels are printed.

- The cans are soaped and cleaned.

- The cans are dried to ensure that the labels will stick.

- Barcode labels are stuck on the cans.

Adjusting of inventory data

Errors in the genebank inventory data are reduced through the introduction of barcode identification and digital weight recording.

The picture on the right shows the steps in recording the inventory data.

- Seed packet (with barcode label) is scanned by the barcode scanner to retrieve the corresponding lot record from the database.

- Seed packet is placed on top of the electronic weighing scale. The current weight of the seed packet is displayed on the scale, and nd is tranferred to computer upon pressing of the control key [F2].

- The new weight can be either committed automatically to the database upon pressing the F2 key (previous step), or after an additional pressing of the [enter] key.

Graphical User interface (GUI)

Seed list creation and label printing

Inventory adjustment

The system in practical use

The IRRI genebank is a participant in the Worldbank upgrading project and has committed to barcoding the entire collection as part of this upgrading. The barcoding exercise was combined with an inventory adjustment, since precise iventory amounts were not kept in the previous information system. During the last three months of 2005 a hight-troughput barcoding and inventory adjustment was carried out for the base collection and part of the active collection. The work was carried out during weekends to minimize disruption of normal genebank work.

A team of 15 staff was able to barcode and do the inventory adjustment for 8,000 - 12,000 seed containers (cans or foil packs) per day, using the equiment and following the procedures described above. During those three months approximately 48,000 cans in the base collection, and 125,000 foil packs in the active collection were barcoded and their inventory adjustment made. Currently the system is used as part of the daily routine work.

Software description

A module in GRIMS (Genetic Resources Information Management System) ties together barcode identification, electronic weight recording and data management in order to minimize human intervention in recording accurate inventory data. The functionality of GRIMS is documented here.

The GRIMS system is developed in Borland Delphi 2006 , in conjunction with the Fast Reports Reporting Tool, and a free barcode font, available from here.

The ICIS[1] Inventory Management System is used to manage lots and inventory transactions. The Technical Documentation of the Inventory Management System is available here.

The source code of the inventory adjustment procedure and labelprinting can be found in the source code repository of the ICIS Delphi Interface project, under the module GRIMS, directory Seed Management,unit "SMT510" and "SMT410", respectively. The source code that allows user to print the labels in a specific position can be found from directory LOV, unit LOVLabel_Position.

Printing of labels

The most essential software needed for printing of barcode labels is the barcode font. The barcode labels can be created using any software that can recognize the barcode font (i.e. Word, Excel,etc). But in IRRI genebank, a reporting tool is used to automatically print the labels to save time and free user from manually formatting the labels. The system developer set up or format the appearance of the report once which can be called from any part of the application.

The tricky part is positioning the labels on the user defined position because the labels used in IRRI is not of continuous format. There is no special barcode label printer used for this activity either, an ordinary laser printer does the job. Since the records are fetched in the database, the manipulation of the label position is done using a temporary table and a simple sql statement.

Reading of data from the barcode scanner

A typical Barcode Reader kit consists of Scanner, Decoder, and Cable that interfaces the Decoder to the computer. The Scanner scans the Bar Code symbol and captures the bars and spaces of the bar code and sends it to the decoder. The decoder translates the bars and spaces into corresponding electrical output and transmits that data to the computer in a traditional data format. A bar code scanner can either have the Decoder built into it, or be "undecoded". Undecoded bar code scanner requires a separate box called an interface or keyboard wedge [2]. The barcode scanners used by IRRI genebank have a built-in decoder.

The program that was developed for IRRI genebank requires carriage return (CR) suffix on the barcode scanner. (The user's manual of the barcode scanner usually provides details on how to set the suffix.) The system recognition of the carriage return key triggers the event of loading the data associated in the scanned barcode label.

Reading of data from the digital weighing balance

IRRI Genebank uses an RS232C standard cable to connect the computer to the weighing scale. A data transfer software is also needed to transmit measurement results directly into the application (unless the developer is capable on low level programming). The supplier of the digital weighing balance usually gives recommendations on what data transfer software to use. Often, the software is bundled with the weighing scale.

The application that was developed for IRRI genebank requires a data input with a carriage return suffix. The carriage return triggers the event of committing the data to the database. But if the user chooses not to automatically commit the data, he can manually press the [ENTER] key to record the changes.

Equipment

- Mettler Toledo Digital Weighing Balance, XS4001S. (search for "XS4001S" here)([picture])

- Mettler BalanceLink Software. (search for "balancelink" here)

- RS232C serial cable

- Symbol barcode scanner. (info here)

- Laser printer

- CILS computer imprintable labels

- software/fonts/etc.

Contact Persons

Dr. Ruaraidh Sackville Hamilton Head, TT Chang Genetic Resources Center IRRI, Los Baños, Laguna Email: r.hamilton@cgiar.org

Ms. Flora de Guzman Genebank Manager TT Chang Genetic Resources Center IRRI, Los Baños, Laguna Email: f.deguzman@cgiar.org

Ella Herrera Prantilla Specialist - Database Administration TT Chang Genetic Resources Center IRRI, Los Baños, Laguna Email: roniela.herrera@cgiar.org